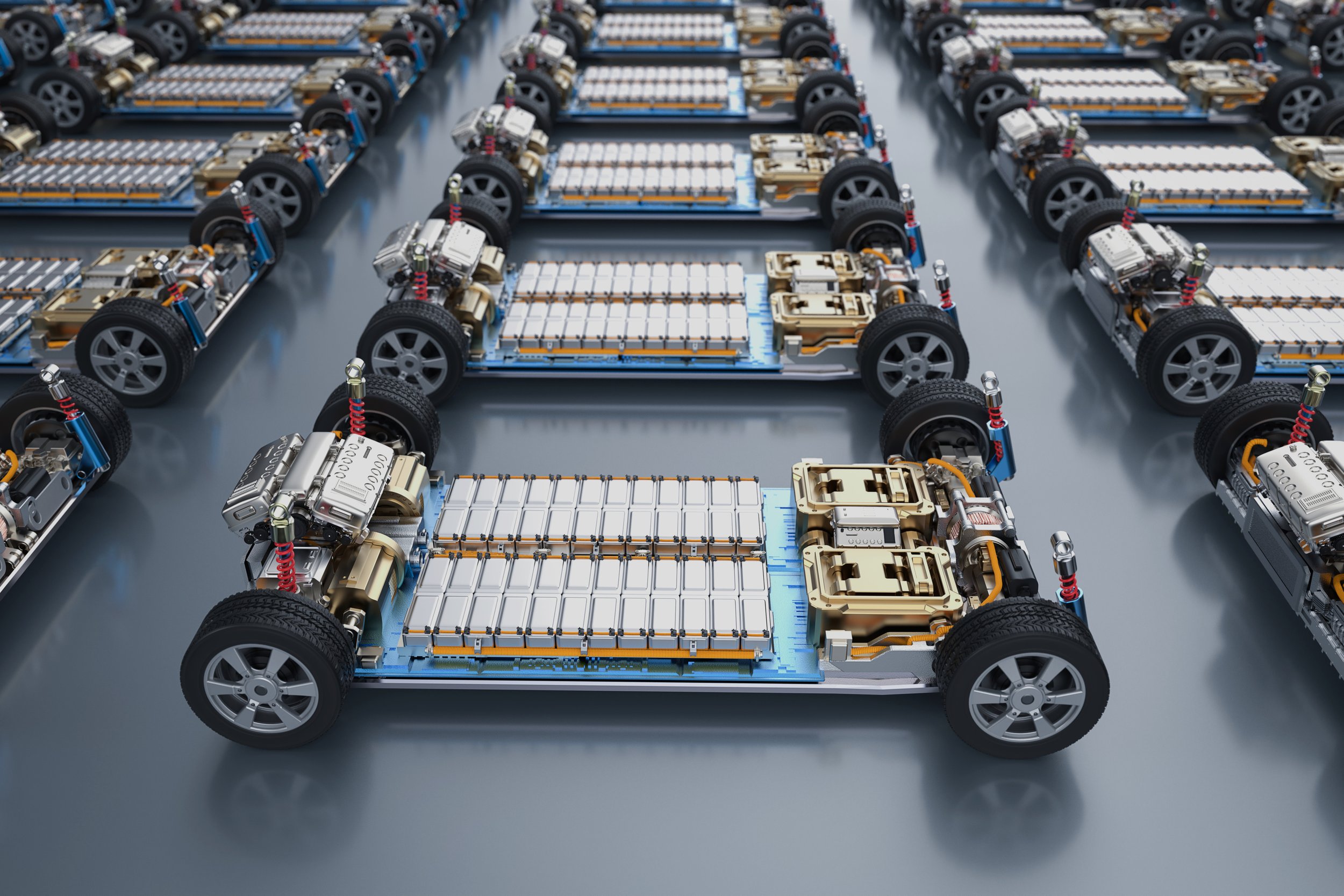

August 8th, 2023 — To date, lithium-ion batteries (LIBs) have been the dominant technology in short-duration energy storage and electric vehicles (EVs). However, in recent years, the fluctuating prices of critical minerals used in LIBs as well as other supply chain uncertainties have prompted the exploration of and advancements in alternative battery technologies. As part of the efforts to continue driving down battery costs, China, a dominant LIB maker, is now betting big on another solution that many other countries might soon feel slightly salty about: sodium-ion batteries (often abbreviated as NIBs after the chemical symbol for sodium, Na).

2023 has been dubbed the breakout year for sodium-ion batteries by many commentators on the Chinese internet. This comes as Chinese battery giants CATL and BYD announced their plan for mass production of sodium-ion batteries earlier this year in order to seize opportunities in the growing NIB market. Preliminary industry data indicates a projected national production capacity of 13.5 GWh by the end of 2023 in China, while the largest NIB project in development in the U.S. will be just 600 MWh.

Why is China so enthusiastic about NIBs?

Sodium-ion batteries are 30% cheaper than the most common type of lithium-ion batteries like LFPs. This cost differential is due to NIBs’ lithium-free composition and low-cost cathodes. Abundant and widely-available sodium supplies ensure a stable and economical supply of raw materials. Additionally, NIBs are safer, have a longer cycle life, and can operate within a wide temperature range (-70 to 100°C) compared to LIBs. However, a significant trade off is their lower energy density, which remains a drawback for their use in EVs.

However, in February, Chinese NIB startup HiNA Battery surprised the market by unveiling the first passenger vehicle equipped with sodium-ion batteries. The test vehicle's battery exhibited an energy density of 140 Wh/kg at the cell level, providing a range of 252 km (Tesla’s Model Y has an electric range of 393-525 km). HiNa aims to achieve a target cost of $50/kWh in large-scale production, a notable difference compared to the $100-$200/kWh values typical of pack-level LIBs. Despite initial energy density limitations, this still makes sense for the Chinese market where short-distance citywide commutes and micromobility solutions like scooters are relatively common and range anxiety is a much smaller concern compared to the U.S. market. HiNA has now raised series A and B rounds, with a valuation of roughly $780M. It is backed by Huayang Group, a Chinese thermal coal producer, and Huawei-owned Habo Investments.

China’s CATL, the world’s largest lithium-ion battery manufacturer, produces sodium-ion cells with a NIB energy density of 160 Wh/kg, approximately 10 Wh/kg higher than many of its competitors. This places them on par with lower-end LIB cells (~160 Wh/Kg), but still well short of regular LIB cells (~300 Wh/Kg). CATL aims to exceed 200 Wh/kg for its next generation NIBs, and anticipates pricing of their NIBs with Prussian blue cathodes at $30/kWh to $45/kWh in mass production. This is a price point that could start to compete with some longer duration grid storage batteries, such as Form Energy which is targeting $20/kWh.

The Chinese market is perhaps uniquely well-suited for NIBs given ongoing technology improvements, cost incentives, easy conversion from LIB production lines, and a receptive market for shorter-range transportation solutions. In comparison, the U.S. has shown less enthusiasm for NIBs, with only a few startups operating in this space. One of the leading NIB makers in the U.S., Natron Energy, has raised roughly $115M to date. (It has been a long journey for Natron Energy, as it spun out of Stanford University over ten years ago.) In the U.S., owing to energy density concerns, the primary applications for NIBs have been thought to be in micromobility and grid storage (diurnal and long duration). One of Natron’s largest investors, United Airlines, is anticipating the startup to contribute to the electrification of their ground operations. Additionally, Liberty Oilfield and Nabor, two prominent oil and gas companies that have also invested in Natron Energy, are exploring the potential use of NIBs in pumps used for fracking and other drilling equipment.

Besides China and the U.S., European startups also have a very active presence in the non-lithium battery space. In Powerhouse’s proprietary database, we track other major sodium-ion battery makers such as UK’s LiNa Energy, Faradion (acquired by Reliance), Sweden’s Altris, and France’s Tiamat. In addition to sodium-ion technology, Powerhouse tracks over 100 startups developing long duration energy storage technologies that use zinc-air, aluminum, vanadium, redox flow, hydrogen, ammonia, liquid-air, compressed air, geomechanics, gravity, heat, and more. And though Chinese battery makers are taking the lead in the development of sodium-ion batteries, startups in the U.S. have also been actively building other non-lithium battery solutions, raising $4.5B to date. Most notably, Form Energy, which specializes in iron-air batteries for long duration energy storage, has raised over $900M.

Numerous startups around the world are exploring different energy storage solutions in order to mitigate the uncertainties arising from the developing lithium-ion battery supply chain. We’ll be watching to see if sodium ion batteries can move down the cost curve far enough to find space in electrified transportation and grid storage.

Special thanks to Huiling Zhou, Dr. Octavi Semonin, and Samuel Wohlforth.

For more analysis from Powerhouse and Powerhouse Ventures, visit our Insights page.